One-stop bearing procurement service provider

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

The preparation work, the method of installing the bearing on the shaft, and the installation of the bearing seat are the same as the standard product.

1. Fill with grease

In order to enhance the effect of dustproof and waterproof, the rubber sealing lip inside the terminal cover and the internal space are filled with 2/3 of space

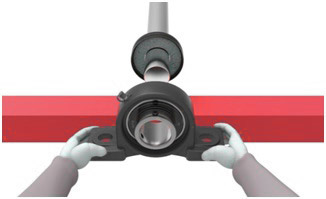

2. Mounted bearing

Put a grease-filled terminal cover on the shaft, and then install the bearing with the seat (the method is the same as the standard product). It is recommended to chamfer the end of the shaft to avoid damaging the rubber sealing lip on the terminal cover.

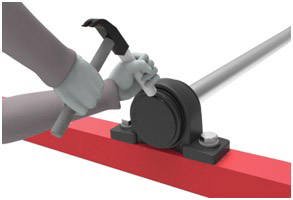

3. Install the terminal cover 1

Press the end cover onto the shaft and press it onto the bearing housing. Note that you cannot directly hit the surface of the terminal cover with a hammer. Use a plastic or wood end to strike the terminal cover at 45 degrees. You can't just hit one position.

Install firmly on the bearing housing.

4. Install the terminal cover 2

Note that you cannot directly hit the surface of the terminal cover with a hammer. Use a plastic or wood end to strike the terminal cover at 45 degrees. You can't just hit one position. You must knock around the entire terminal cover until it is firmly installed on the bearing housing.